The DIY orgone pyramid process is simpler than it seems. It requires few materials and does not entail great dangers beyond some basic precautions. Below we will explain the detailed process so you will be able to start your creations.

MATERIALS NEEDED TO MAKE AN ORGONITE PYRAMID

- Protective gloves, googles and mask (mandatory)

- Silicon mold (mandatory)

- Glass cup and spatula (mandatory)

- Scale (mandatory)

- Polyester or epoxy resin (mandatory)

- Metal shavings or wire (mandatory)

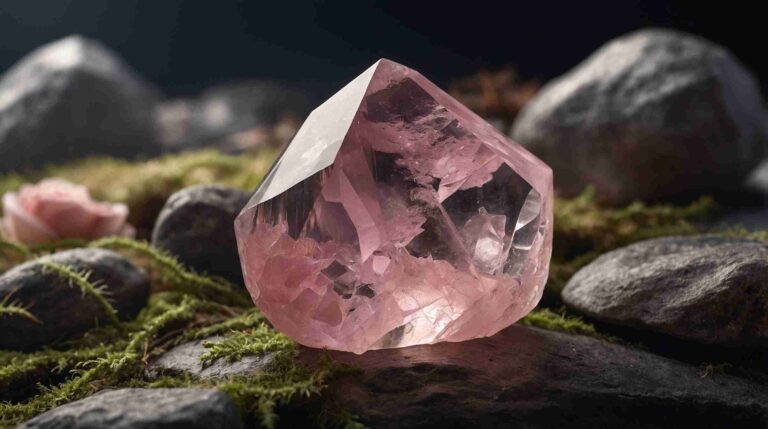

- Quartz crystal point (optional)

- Orgone healing crystals (mandatory)

- Sacred symbol stickers (optional)

- Color ink for resins (optional)

- Glitter (optional)

- Sandpaper, polisher and polishing pads (mandatory)

- Light and light bases (optional)

STEP 1. PREPARE YOUR WORKSPACE

The first step is to prepare the work area. Whenever possible, work in an outdoor area or, failing that, a well-ventilated area. Regardless of whether you achieve these working conditions, this does not exempt you from working with a mask and protective equipment. Wear comfortable clothes that you don’t mind getting stained. Use a flat worktable in good condition. If working indoors, cover furniture and objects that you do not want to get stained.

STEP 2. CREATING COPPER COILS AND WRAPPING COPPER WIRE AROUND A QUARTZ CRYSTAL POINT

The conductive metal is essential in the creation of an orgone generator. Sometimes you will add metal shavings, other times small spirals, and sometimes both. Wrapping a quartz crystal in copper wire is a common practice to link the crystal with the lower area where the other elements are, enhancing the interaction between the elements involved with the orgone energy. Let’s quickly see how to create these elements.

HOW TO MAKE COPPER COILS

The process of creating copper coils is really simple.

- Take a copper wire about 40 cm long (15.75 inch), either purchased or stripped from a wire.

- Find the center of the wire, either by eye or with a tape measure, and hold it at that point with pliers.

- Bend one side of the wire until the tip touches the tip on the other side.

- Holding the wire from the center with the pliers begin to bend the sides in a spiral around the center.

- Continue making the spiral with each half of the wire until it is completely consumed.

- Using the pliers, bend the tips slightly and cut off the excess of material.

Since a picture is worth a thousand words, here you can see a detailed video with the process step by step.

HOW TO WRAP A COPPER WIRE AROUND A QUARTZ CRYSTAL POINT

There are many ways to wrap a copper wire around a quartz crystal, and all of them are simple.

One option is to use pliers to bend one of the corners of the wire and accommodate it to one of the tips of the quartz crystal, and from there, manually wind the wire. You can also use a workbench to hold the quartz crystal while you roll the copper around it.

In general, it is a process that does not entail difficulty. For an easier viewing, a video is attached.

To take in consideration is the fact that you must always leave one end of the wire uncut so that the quartz crystal (which is normally located at the vertex of the pyramid) is always in contact with the other orgone energy crystals and shavings of metal that can be added in the lower layers.

STEP 3. PREPARING THE RESIN

Remember that in the articles section you can find a detailed explanation of the types of existing resins, and in the reviews section you will find a comparison of epoxy resins on the market. Whatever product you choose, the first thing is to know the quantities and proportions you should use. Also remember to always use gloves and a protective mask.

HOW MUCH RESIN DO I NEED TO MAKE AN ORGONE PYRAMID?

The first thing before starting is to know what quantities should be prepared. Normally, if you have purchased a silicone mold, it will already come with instructions, quantities, and recommendations. The same for the resins, they will come with clear directions. But just in case, let’s review some concepts.

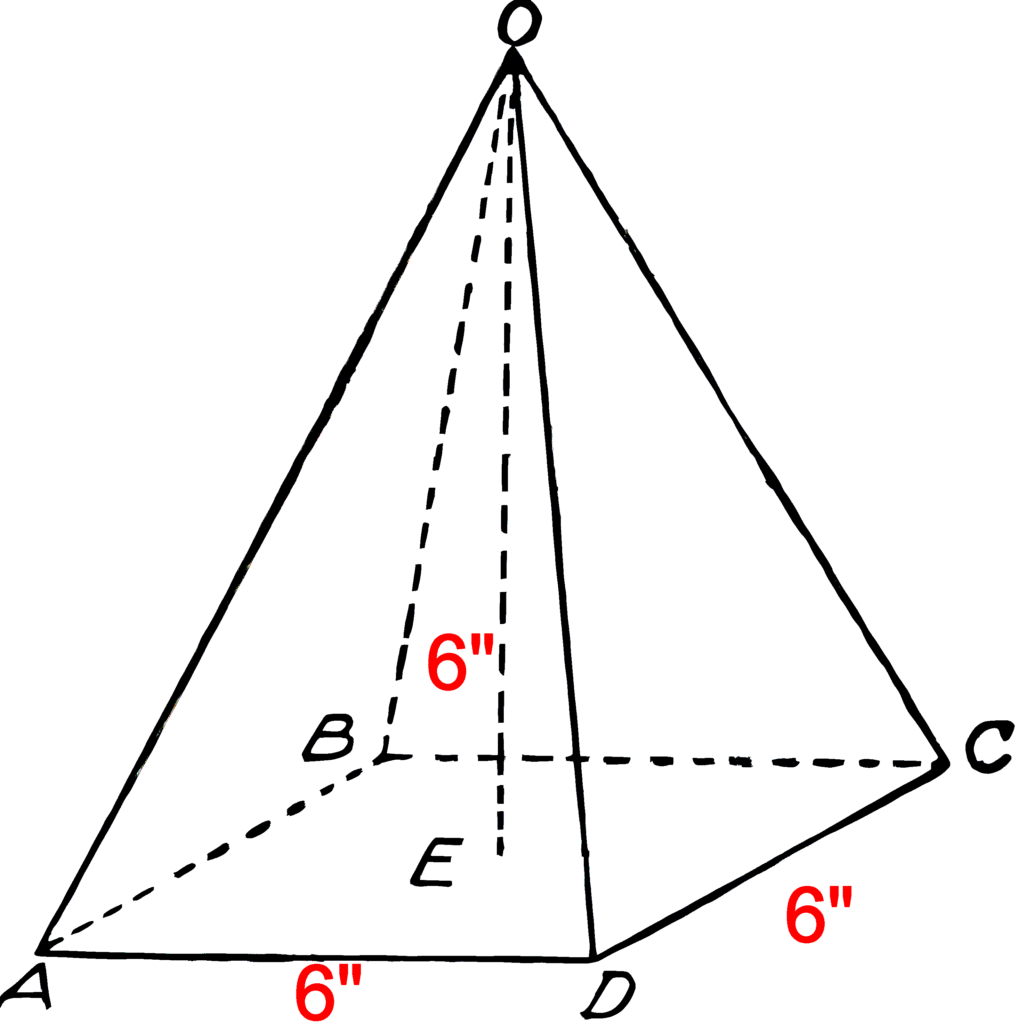

Let’s say you want to fill a pyramid that is 6″ x 6″ at the base, and 6.5″ high. Normally the pyramid is never filled completely, so, to keep it simple, let’s assume that we are going to fill a volume that is 6″ x 6″ x 6″ high.

The first thing we will do is calculate the volume of the pyramid, and therefore, the total volume of resin that we will have to use. For this we will use the following formula:

V = (AD x DC x EO)/3

In our case, the distance between A and D is 6″, as is the distance between DC and EO. Therefore, the expression becomes:

V= (6” x 6” x 6”)/3 = 72 in3

Therefore, the calculation shows that we will have to use 72 cubic inches of resin to completely fill the pyramid (always with a small margin because remember that the pyramid is 6.5” high).

The subsequent step requires obtaining information from the manufacturer. It is essential to determine the mixing ratio between the resin and the catalyst, as well as the densities of each component. When using polyester resin, only the resin’s density is typically considered due to the minimal proportion of the catalyst. However, with epoxy resin, the densities of both the resin and the catalyst/hardener must be taken into account.

Suppose we have purchased an epoxy resin with a mixing ratio of 1:1 in volume, that is, one part resin and one part hardener, and a density for the resin of 0.0657 lbs./in3 and 0.0332 lbs./in3 for the hardener.

If we need a total volume of 72 in3, and the mixture is with a 1:1 ratio, we need 36 in3 of resin, and the same amount of hardener.

From here we have several ways to work. If we have beakers with volume markings or other similar elements, it will be enough to pour 36 in3 of resin and the same amount of hardener, however, if we don’t have these items and have to work with a scale, then we must consider the density.

In our example, we have for the resin that we’ll need a weight of 36 in3 x 0.0657 lbs/in3 which is 2.37 lbs (37.92 oz), and for the hardener that will be 36 in3 x 0.0332 lbs/in3 = 1.20 lbs (19.2 oz). This calculation obeys the expression weight= volume x density.

Once we have the weights calculated, it is only a matter of weighing the indicated quantities with the scale and mixing them.

So far we have learned how to fill the mold of an orgone pyramid with epoxy resin leaving a small safety margin. We have also seen how to proceed with the preparation whether we have beakers with volume marks or if we work by weight with a scale. But what happens if we want to fill our pyramid with several layers of resin?

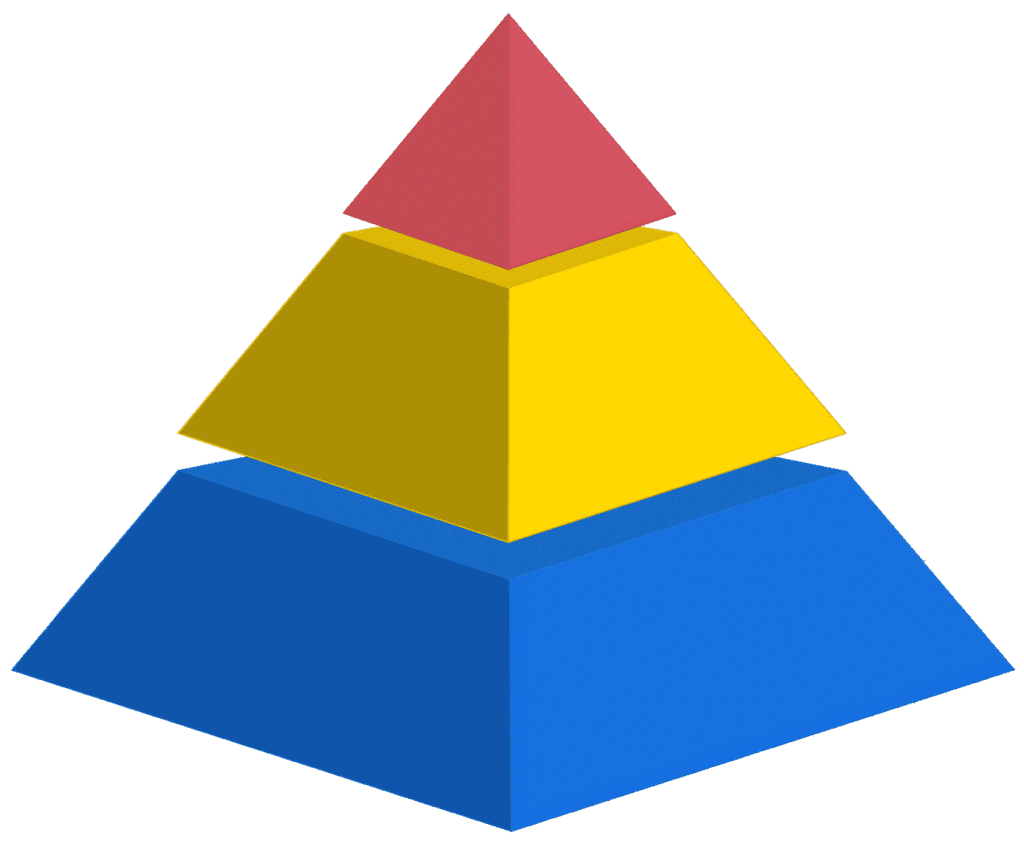

Imagine that we want to prepare three different layers: a first with a quartz crystal rolled in copper, a second with some orgone energy crystals and a colorant for the resin, and a third on the base with metal shavings. Each of the layers will not be applied until the previous one is dry. How do we do it?

For the first layer (the top in red color) we should proceed as we have seen before, just calculating the volume of the pyramid.

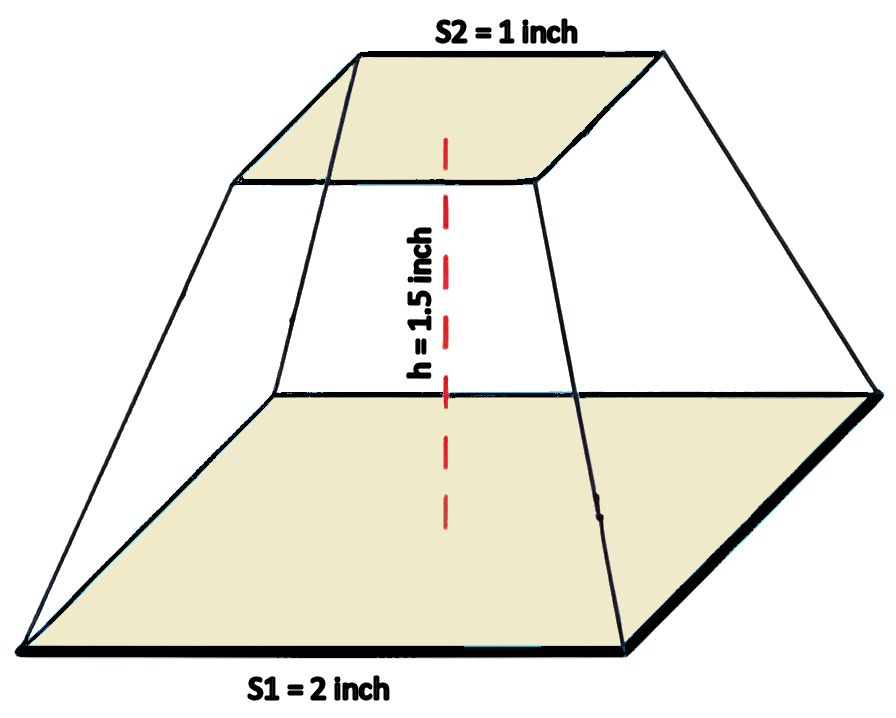

The problem arises with layers 2 (yellow) and 3 (blue). Here, we are dealing with a pyramid frustum, and the method for calculating the volume differs from that of a regular pyramid. Consider the following example::

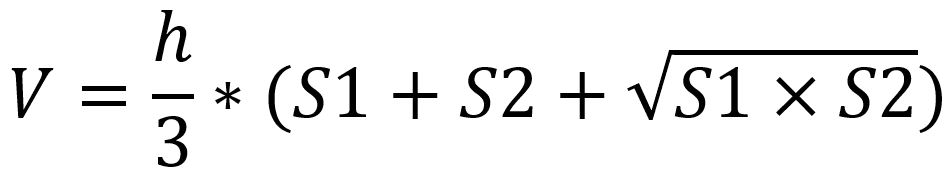

In this case, we will use the following expression to calculate the volume:

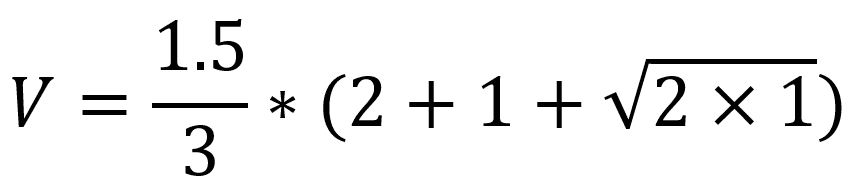

In our example that will be:

that gives a result of: 2.21 in3.

The subsequent steps are as previously described, which involve considering the mixing ratio between resin and hardener, as well as the density to convert volume values into weight for scaling and mixing purposes.

Now that it is clear how to calculate our resin needs, the next step would be mixing it.

HOW SHOULD I MIX THE RESIN TO MAKE AN ORGONE PYRAMID?

In the process of mixing the resin, whether it is polyester or epoxy, our main enemy will be the formation of air bubbles. It is imperative to mix the ingredients slowly to avoid their formation. On the other hand, the mixture should be uniform, meaning that you’ll need to stir the ingredients for several minutes to ensure there are no remnants of unmixed material on the container’s walls or edges. If using an electric mixer, select a low speed to avoid the formation of bubbles.

For the mixing spatula or tool, the ideal materials are metal or heat-resistant glass. If these are not available, wood or plastic can be alternatives, though they are less preferable. Wood may leave residues in the resin and deteriorate over time, while certain plastics may react with the resin and also degrade.

The choice of container is crucial. Some resins are exothermic, meaning they generate heat when mixed with a hardener. It’s important to select a container that can withstand this heat, such as Pyrex glass. If Pyrex is not available, a metal container may suffice, but be mindful of heat conduction during handling. A plastic container is suitable if it is chemically inert to the resin and can tolerate high temperatures without warping. Often, resin manufacturers provide appropriate cups and tools for use with their product.

If mixing the components results in numerous air bubbles, there are several effective methods to remove them. One of the simplest is to submerge the container with the mixed resin into another container filled with hot water. Within a few minutes, the bubbles will begin to dissipate, and this will occur before the resin sets.

LET’S GET STARTED! THE FIRST LAYER, PLACING THE WRAPPED QUARTZ CRYSTAL POINT

The first layer, the one that will be closest to the vertex of the pyramid, will consist of a layer of resin that will encapsulate the quartz crystal wrapped in copper wire that we have prepared previously.

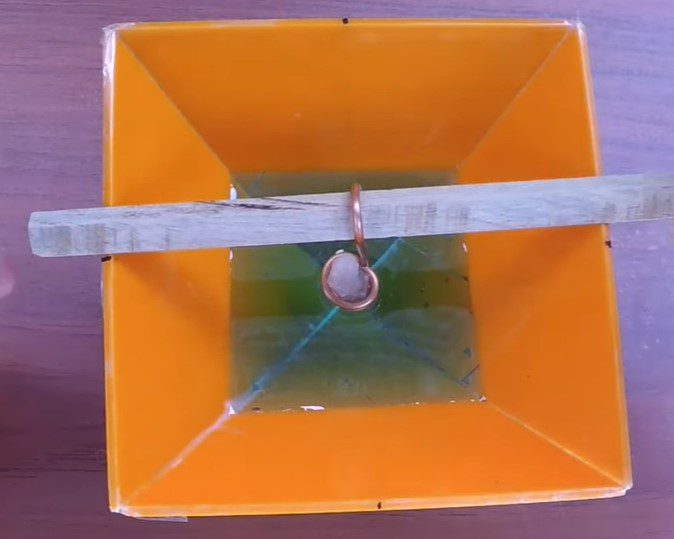

The initial step involves suspending the quartz crystal to ensure it does not contact the pyramid’s apex. Various methods exist for this: one method is to adhere one end to a cardboard piece and slot it between the pyramid’s walls. This method is straightforward, yet it may present challenges when detaching the cardboard from the quartz and during the resin pouring process.

The second, and more recommended option, involves using the excess copper wire from the quartz crystal to hang it from a wooden strip or similar object that we will position at the top of the mold. This requires ensuring that a sufficient length of wire remains when wrapping it around the quartz.

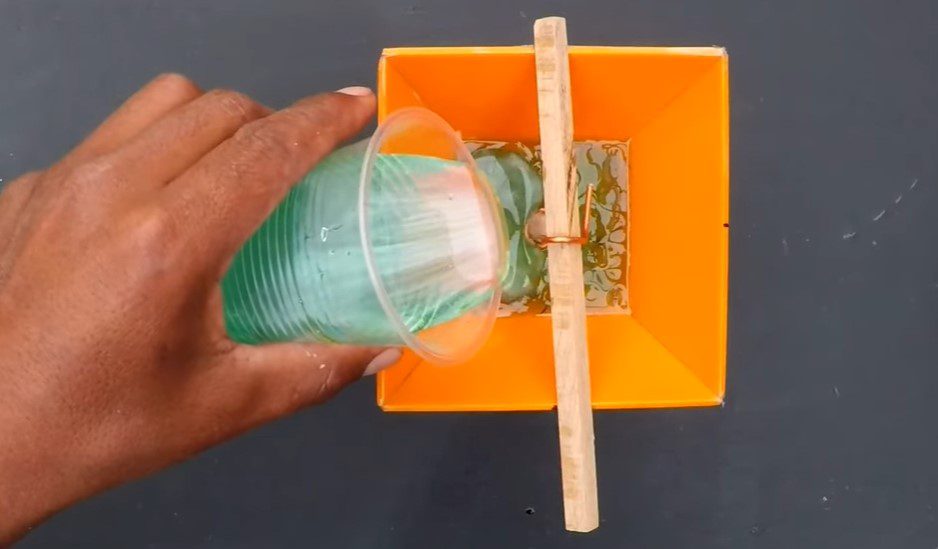

The subsequent step involves preparing the resin, as outlined previously. We will determine the required quantity, as previously discussed, mix the resin and hardener gradually, and then pour it meticulously until the quartz is fully immersed.

As the resin begins to harden, we will be very aware of the formation of air bubbles. To prevent formation, we will spray the surface with a little isopropyl alcohol. You can also use a hair dryer and apply heat. After the curing time has passed, we will be ready to proceed with the second layer.

LET’S CONTINUE WITH THE SECOND LAYER! RESIN WITH ORGONE CRYSTALS

To prepare the second layer we will use the calculation method set out in the previous sections, considering that in this case we will have to calculate the volume of a frustum of a pyramid.

Once the quantities of resin and hardener are determined, we will proceed with the mixing process. As mentioned previously, this should be done slowly to prevent the creation of bubbles.

After mixing the resin with the hardener, we will add the resin ink. There are many types of inks, some liquid, and others powder that you can find in the orgonite supplies section. After mixing the resin and ink we will add a little glitter.

We’ll pour the resin into the mold atop the already dry layer and then proceed to add the orgone energy crystals. Remember, you have a properties chart available to select the healing crystals that best suit the desired properties for your orgonite.

Once the resin is partially hardened, we will spray isopropyl alcohol to prevent the formation of air bubbles or apply a dryer. Finally, if we want the quartz crystal point to be in contact with the third layer, we will leave the excess copper wire, and otherwise we will cut it with pliers.

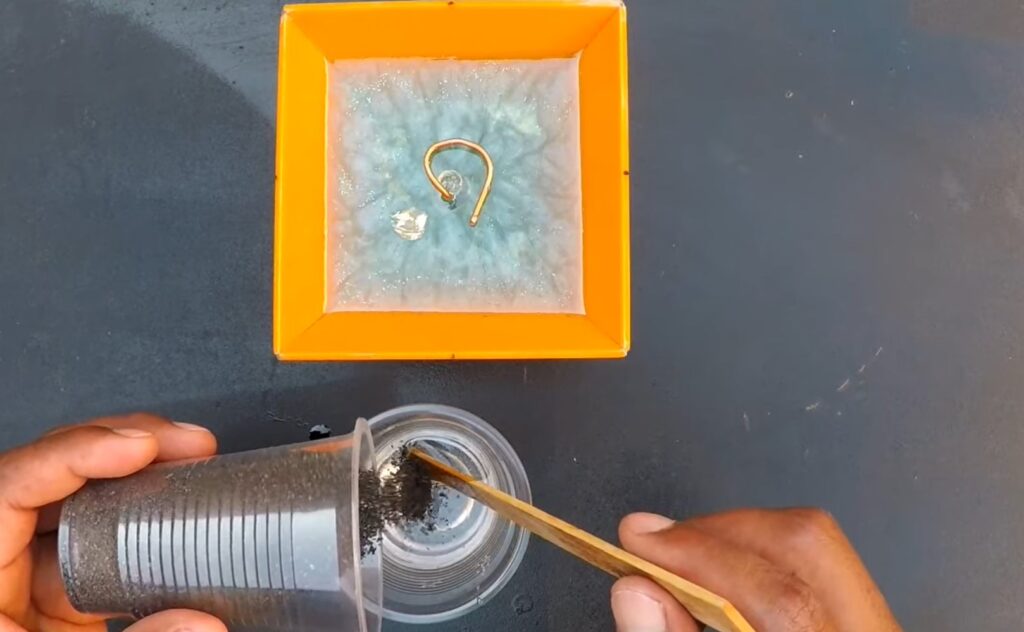

THE LAST ONE: THE METAL SHAVINGS

We are going to continue our orgonite pyramid design by preparing the last layer, in which we will mix the resin with our metal shavings that will act as orgone accumulators.

The measurement will be conducted as in the previous section, calculating the volume of the mold’s last section, which is also a truncated pyramid. Following that, we will mix the components as previously learned, and upon readiness, we will incorporate the metal shavings.

Opinions vary on this matter. Some experts argue that to maintain a 50/50 ratio, an equal weight of metal shavings and resin should be used. However, we believe that such a strict proportion is not necessary. While metal shavings should certainly be included in a substantial amount, it’s not essential to adhere strictly to the aforementioned ratio. A minimum of 20% by weight of metal shavings is advisable, with the option to increase this percentage as desired. For instance, if you calculate that you’ll use 3 oz of resin in total (after mixing both components), you should incorporate at least 0.6 oz of metal shavings.

After incorporating the metal shavings, continue to blend them gently with the resin throughout the process. Transfer the mixture into the mold and allow it to cure for the duration specified by the manufacturer. Ensure to mist the surface with isopropyl alcohol. Your orgone pyramid is now prepared for the final step.

DEMOULDING AND POLISHING OF OUR ORGONE PYRAMID

The demolding process is generally straightforward with a silicone mold. However, if you’ve used a custom-made mold, it might pose more challenges and need additional time spent on polishing.

The first step will be to trim any excess of resin from the edges of the pyramid using a sharp knife or sandpaper.

Next, you must proceed to polishing to give it a perfect finish. As mentioned, this is very important if you are working with DIY-molds. In the resin polishing process, we will need the following materials:

- Sandpaper with the following grits: 180, 240, 320, 400, 800, 1000, 1500, 2000, 3000 and 5000.

- Polishing machine

- Polishing pad (normally supplied with the machine)

- Polishing liquid for resins.

- Wax

- A damp cloth and a dry one.

- A pencil (optional)

THE POLISHING PROCESS BEGINS. FROM THE COARSEST GRAIN SANDPAPER TO THE FINEST

As you probably know, the thickest sandpaper has the lowest numbering. Thus, we will start working with 180 grain sandpaper.

We will attach the sandpaper to the machine and begin the process at low speed, and then increase it. It is very important to go through all the corners and faces of the orgone pyramid. We will see that in the process, the pyramid loses shine and becomes dull. It is normal since we are working with the coarsest sandpaper. We will gain shine as we progress and especially at the end of the process.

The length of time for sanding with each grit is not predetermined; it is essential to ensure that all surfaces and edges are sanded. Once we observe that no more sawdust is being produced, we can cease sanding. To verify that every corner and face has been sanded, a pencil can be used. By marking all the areas before beginning, we can be certain we have sanded them when the pencil marks are no longer visible.

We will repeat the process with each of the sandpapers, from the thickest to the finest, that is, from the highest numbers to the lowest. Very important: between sandpaper and sandpaper we will ALWAYS wipe with a damp cloth to remove grains that have come loose and then we will dry the pyramid with a dry cloth before continuing with the next sandpaper.

From grit 1500 and 2000 we will see how the shine lost at the beginning of the process is restored.

THE LAST TOUCH. FINAL POLISHING AND WAXING.

Once the 5000 grit sandpaper has been applied, your pyramid should look shiny and soft to the touch. It is time to use the polishing liquid and execute the last steps.

We will pour a small amount of liquid on one of the faces of the pyramid and spread it with our finger over the entire surface. Next, we will place the polishing pad on the sanding machine and proceed as we did with the sanding process: starting at slow speed and increasing to medium speed. When we finish with one face of the pyramid, we will continue with the next ones.

To finish and give the last touch of quality, with a dry cotton cloth we will spread a little finishing wax and apply it to each of the faces of the pyramid using circular movements.

DID YOU THINK WE WERE FINISHED? A COUPLE MORE DETAILS FOR YOUR MASTERPIECE

Now that we have our orgone pyramid almost finished, it is time to increase its beneficial effects and beauty with a couple of supplements. Both are optional, but they will undoubtedly give a final touch of quality to our creations that our clients will appreciate.

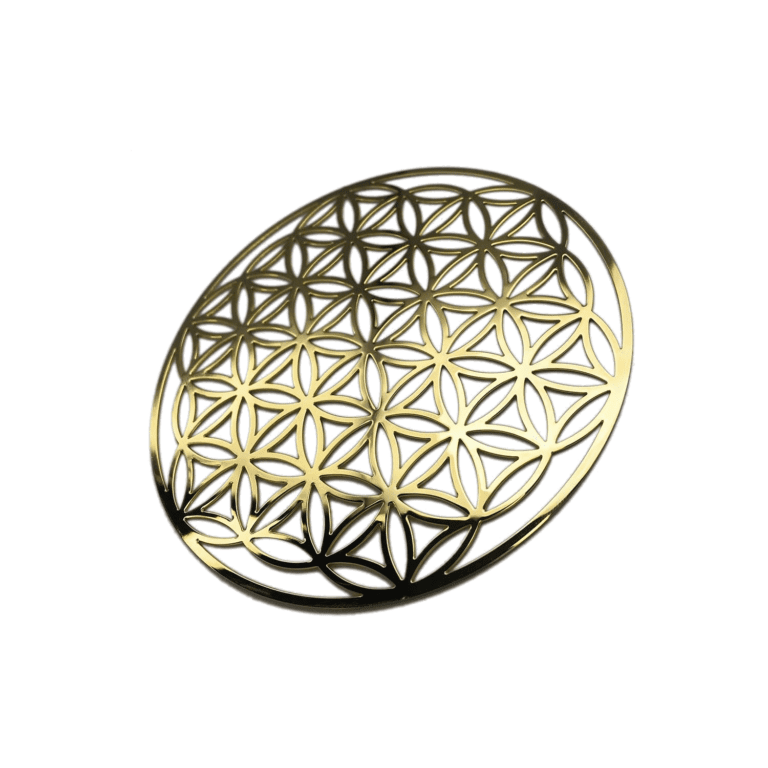

The initial step is to affix a sacred geometry symbol. For simplicity, we’ll select from the readily available options and adhere it to a face of the pyramid. If feasible, opting for metal labels is recommended, as they enhance the capture and conversion of orgone energy into positive orgone energy. With a variety of sacred geometry symbols available, make an informed choice using the properties chart provided.

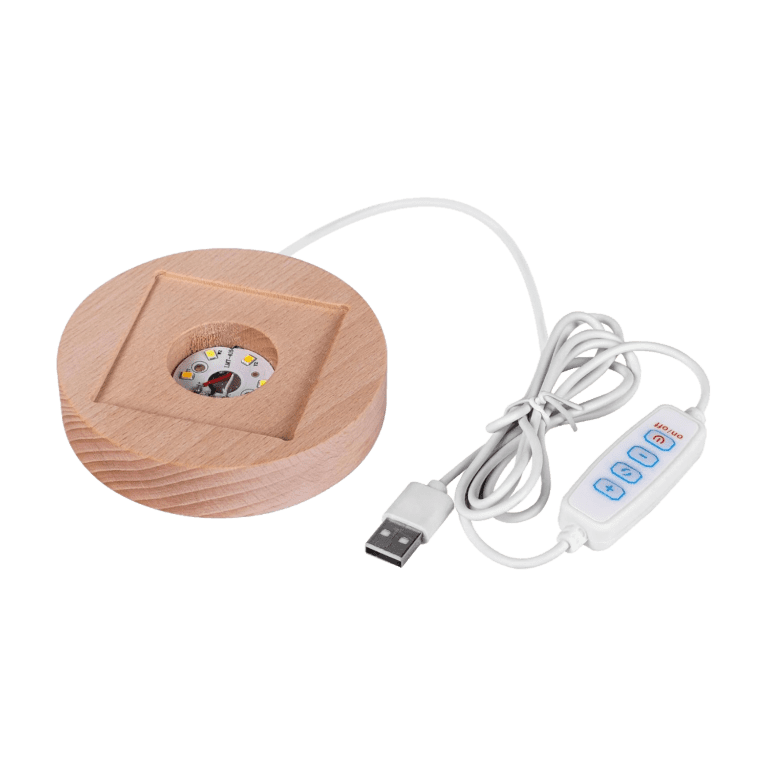

Finally, you have the option of purchasing an LED lamp. Whether the pyramid is for you, or if you are just starting out in the DIY orgone pyramids business, these types of lamps can give your creation unprecedented spectacularity. They are not expensive solutions; our recommendation is that you take a look at the available options and decide what suits you best.

Additionally, a video is available here to illustrate most of the processes described in the article.

That concludes the process of creating an orgone pyramid. We trust you’ll find this information beneficial. Keep in mind the myriad of options available for incorporating various layers of resin, healing crystals, colorants, glitter, and more. Delight in the crafting experience!